So you need to get a custom plastic part or product, but you don’t know how to get it made. There are many different types of plastic moulding available to get your product manufactured.

Is it large or small? Flexible or stiff? Round, Square, Star shaped? Do you need a few or a few thousand?

We hope this guide will explain the different kinds of moulding processes available today to help you discover the best way to manufacture your product.

What is Plastic Moulding?

Plastic moulding is the process of manufacturing, by shaping liquid or pliable plastic material using a rigid frame called a mould or tool.

Vacuum forming is when a sheet of plastic is heated to a forming temperature, stretched onto a single-surface mould, and forced against the mould by a vacuum.

Types of Plastic Moulding

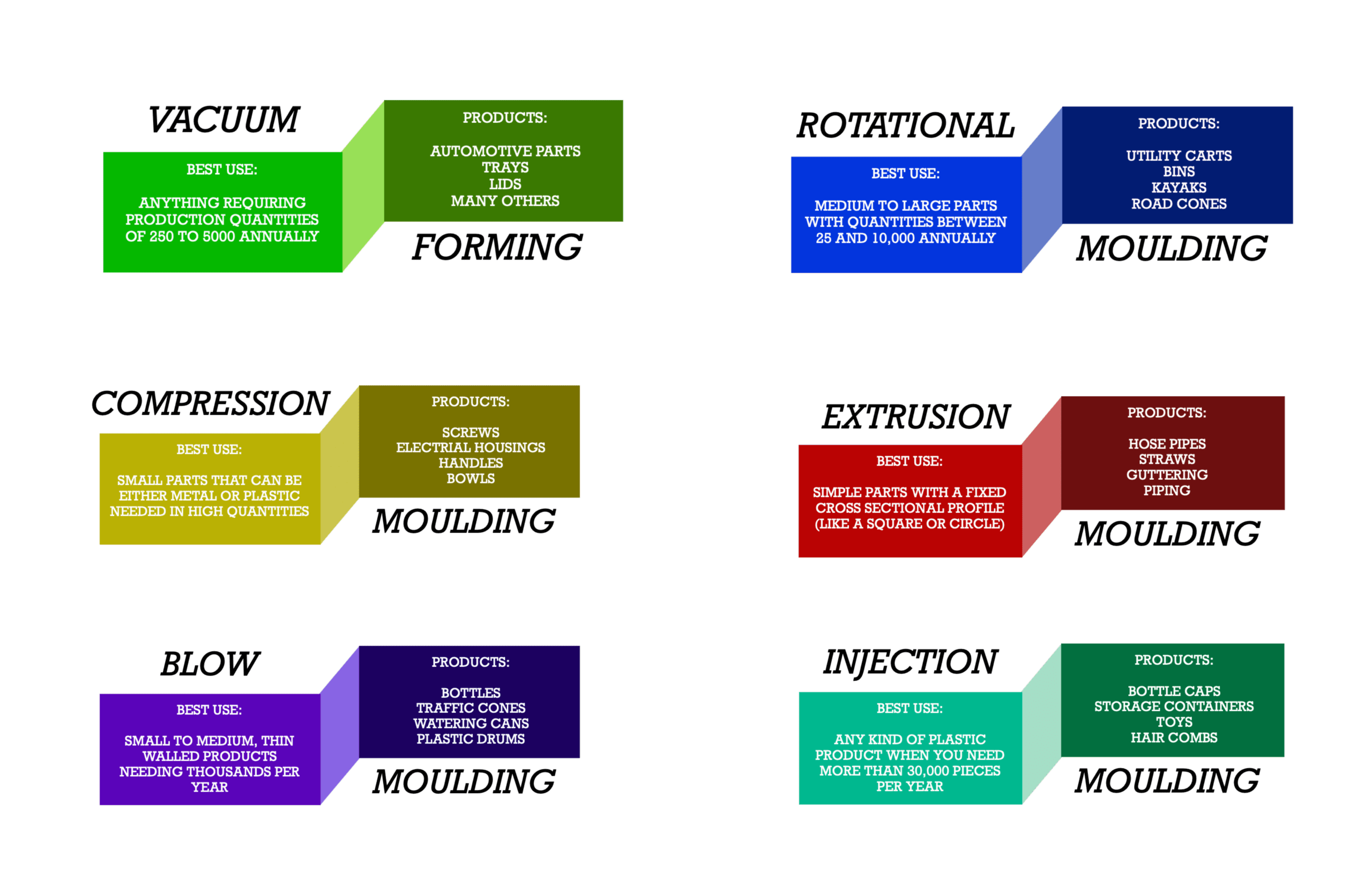

The most popular types of plastic moulding are vacuum forming, blow moulding, rotational moulding, compression moulding, extrusion moulding, and injection moulding. Below we will look at all these processes so you can decide which one best fits your need.

Is Vacuum Forming right for you?

Now that you know all about the different types of plastic moulding… is vacuum forming the right option for you?

If you’re still not sure, fear not! Our team is here to help, call us today on 01388 777 700 or email us and a member of the team will be in touch to discuss your plastic moulding project.

You can also find out more about what we do and keep up to date with all our latest news by following us on Twitter, Facebook, Instagram and LinkedIn.