For this case study we are going to explain ESD materials. Understanding the needs of our customers is paramount to what we do here at Plastic Mouldings Northern Ltd, offering the best materials for each project is vital in ensuring complete customer satisfaction.

Many of our clients work with electronic parts and often require solutions for transporting and handling them safely and securely. We manufacture trays and dividers to the specific needs of customers in a range of materials to suit each specification. In order to get the right material we first must understand the different classifications used when handling electronic parts.

Electrostatic discharge (ESD) is the transfer of accumulated electric charge from one object to another. The transfer can cause damage. If an electronic component has stored energy and its terminals make contact with a low resistance ground path, a rapid discharge will occur with an associated current spike. If not designed to handle the spike, internal circuitry can be damaged or destroyed. If, instead, the ground path is resistive, the discharge rate is slowed, and damage avoided.

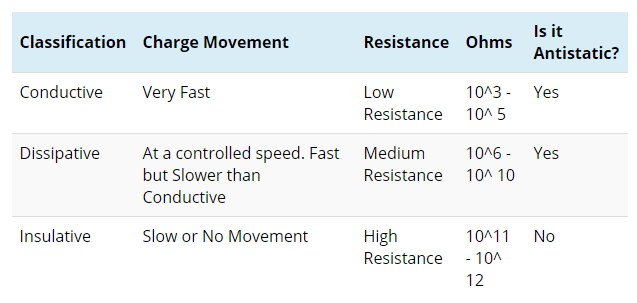

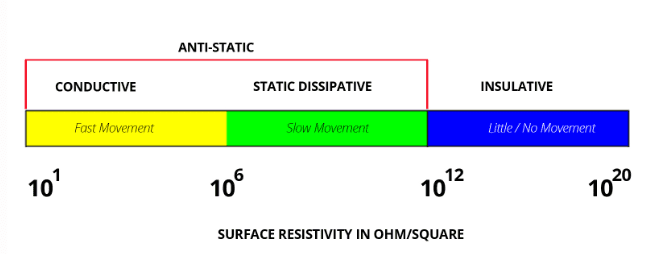

For ESD control purposes, materials are classified by how quickly electricity moves through the material. The speed is referred to as the “resistance” of the material i.e. how strongly the material resists charge movement.

Materials for protection and prevention of ElectroStatic Discharge (ESD) can be categorized into three distinct groups – separated by their ranges of conductivity to electrical charges. The speed is measured in Ohms and is typically displayed in powers of 10 (example 10^3). The lower the number, the more conductive the material and may be considered “Antistatic”.

Anti-Static

Preventing the buildup of static electricity. Reducing static electric charges, as on textiles, waxes, polishes, etc., by retaining enough moisture to provide electrical conduction.

Dissipative

The charges flow to ground more slowly and in a somewhat more controlled manner than with conductive materials. Dissipative materials have a surface resistivity equal to or greater than 1 x 105 Ω/sq but less than 1 x 1012 Ω/sq or a volume resistivity equal to or greater than 1 x 104 Ω-cm but less than 1 x 1011 Ω-cm.2

Conductive

With a low electrical resistance, electrons flow easily across the surface or through the bulk of these materials. Charges go to ground or to another conductive object that the material contacts or comes close to. Conductive materials have a surface resistivity less than 1 x 105 Ω/sq or a volume resistivity less than 1 x 104 Ω-cm.

Insulative

Insulative materials prevent or limit the flow of electrons across their surface or through their volume. Insulative materials have a high electrical resistance and are difficult to ground. Static charges remain in place on these materials for a very long time. Insulative materials are defined as those having a surface resistivity of at least 1 x 1012 Ω/sq or a volume resistivity of at least 1 x 1011 Ω-cm.

We hope that helps you understand ESD materials better, if you’re looking for some conductive, dissipative or insulated vacuum forming give our sales team a call on 01388 777 700 or email sales@pmn-ltd.co.uk.

You can also find out more about what we do and keep up to date with all our latest news by following us on Twitter, Facebook, Instagram and LinkedIn.