Examples: what are we capable of?

We have produced vacuum formed packaging for a host of practices:

- Beverage can, food can, and aerosol packaging

- Electronic part packaging

- Automotive parts packaging

- Medical instrument packaging

- Veterinary vaccination packaging

At PMN we are unique in the fact that we are able to offer the full packaging solution.

Our suite of machine sizes, adaptive approach and wealth of experience allows us to create bespoke returnable packaging, transit trays, thin gauge trays and dust covers of all sizes. We can form up to a maximum size of 3500mm x 1500mm and up to 600mm in depth whilst our multiple 5-axis CNC machines allow us to consistently provide products and services that exceed customer expectations and completely meet requirements.

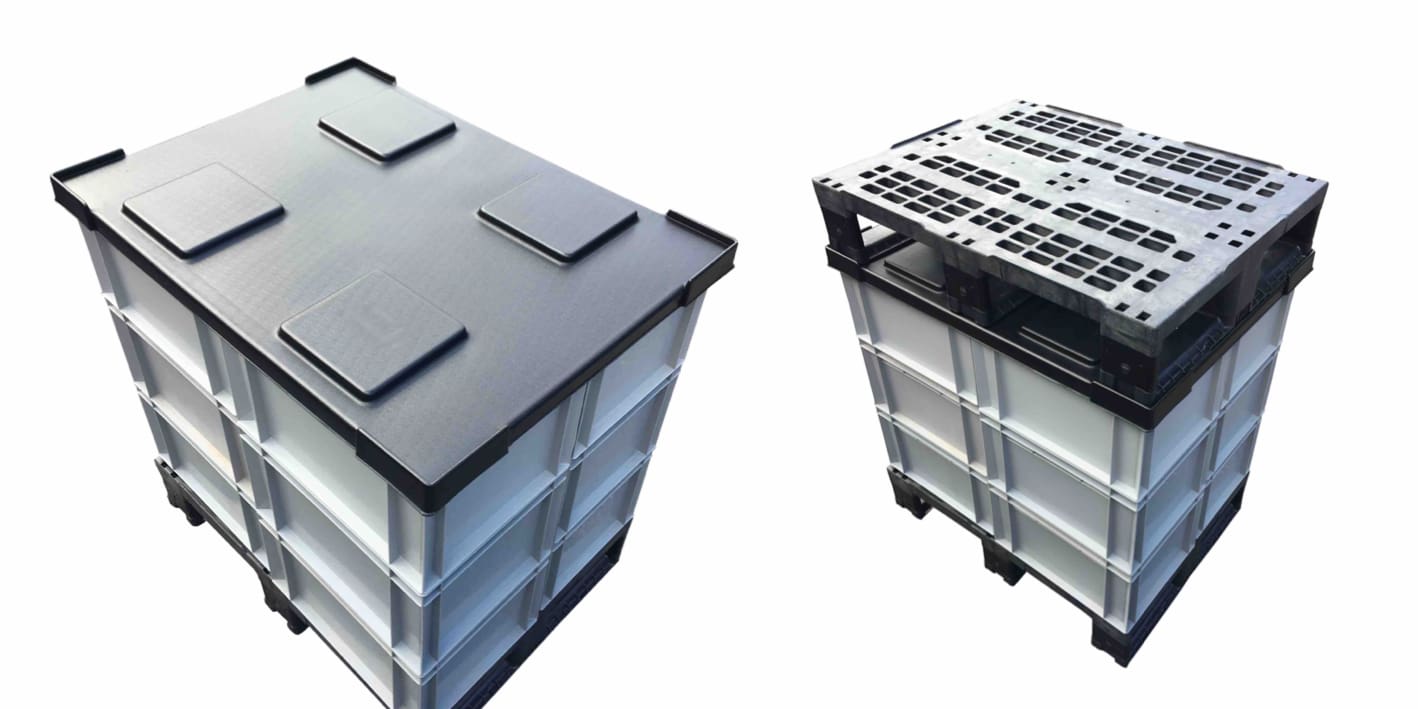

As well as a vacuum forming manufacturer, we are one of the UKs leading supplier of Returnable packaging products such as Euro containers, Pallet boxes (FLC’s) and pallets which really sets us apart from the competition.