As one of the UK’s leading vacuum forming manufacturers, we boast a large range of machinery and over 150 years of combined experience. With 7 vacuum forming and 3 state-of-the-art CNC machines, our capabilities are extensive. Our impressive machinery matched with our unparalleled knowledge and experience means we are your go to partner for vacuum forming.

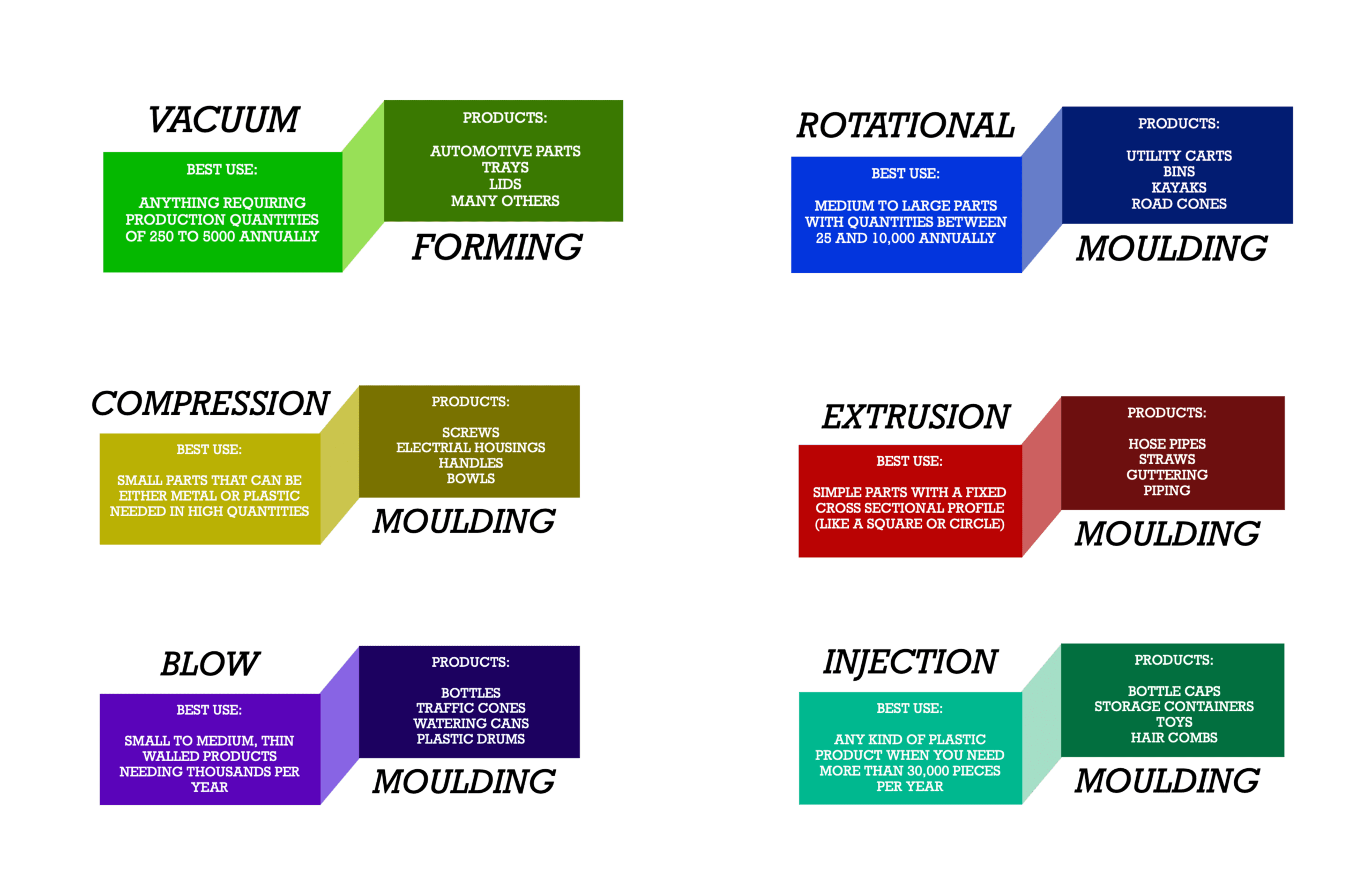

How it works, why Vacuum forming?

Vacuum forming or Thermoforming is the process of turning flat sheets of plastic into a bespoke 3D parts using a specific tool.

The process is ideal for small to medium size production runs thanks to lower upfront costs on tooling and the allowance of a flexible approach to manufacturing due to a wide range of machines with varying capabilities.

We can vacuum form up to 3500 x 1500 mm with up to 15mm material thickness in a vast range of plastics, with a huge focus on recycled and recyclable plastics which perfectly aligns with our ethos as a returnable packaging specialist.

If you have a vacuum forming project that we may be able to be of assistance with but have any queries or confusions, we can arrange site visits and consultations to ensure that we completely understand your project and requirements meaning that you get the maximum output from our services.

Materials available:

- ABS

- HDPE

- HIPS

- ESD

- FR (Fire Retardant)

- High Heat Material

- PP

- PETG

- APET

- PMMA Acrylic

- Acrylic capped ABS

150 +

Years of experience

7

Vacuum Forming Machines

3

CNC Machines

3

Sites

The stages of vacuum forming

Design and development: Our expertise can take a concept or idea into production. We 3D draw the part or tray to suit your needs, meaning this can be checked thoroughly prior to prototyping. Our software allows us to scan 3D components to ensure that the final product will meet your needs precisely.

Prototyping: After drawing sign off, we produce a softer, modelboard tool as a cost saving way of proving out the design and ensuring the product will fit its use before an aluminium tool is produced.

Production tool: Once prototypes are approved, an aluminium tool is used for product manufacturing with the option for temperature-controlled tools.

CNC trimming: If trimming is required, products are moved to the next stage of production where a CNC jig is produced to hold the part whilst our high precision 5 axis CNCs trim within a tolerance of 0.2mm.

Taking your project from design to production.

We specialise in vacuum formed packaging, offering a wide array of capabilities to meet your packaging needs.

We prioritise collaboration with our customers throughout the vacuum formed packaging design and development journey, ensuring top-notch quality products and unparalleled ‘A’ level service in our industry.

Our adaptable approach, extensive machinery, and wealth of experience enable us to cater to projects of all sizes. We are your vacuum formed packaging partners, delivering excellence in design, manufacturing, and service.

We are a vacuum forming company that specialises in vacuum form custom finished parts across a range of industries.

At Plastic Mouldings Northern, we specialise in vacuum form custom finished parts using a wide range of plastic materials to meet your specific requirements.

Our expertise extends to various plastics, including ABS, Acrylic, APET, ASA, ESD, HIPS, HDPE, PVC, Polycarbonate, Polypropylene, PETG, Polystyrene, Fire Retardant Material, PMMA, and VCI. We have the capability to work with material thickness ranging from 200 microns up to 15mm.

Our advanced vacuum forming capabilities allow us to create parts with maximum dimensions of 3500mm x 1500mm, subject to depth restrictions, and a maximum depth of 600mm, depending on the size and specific requirements of the plastic vacuum form project.

We have the capability to vacuum form any design for your contract moulding needs.

At Plastic Mouldings Northern, we have the capabilities to vacuum form almost any design. Our team has 100+ years of combined skills and experience and will always suggest a cost-effective solution for your contract moulding needs.

recent Vaccum Forming

case studies

Our Vacuum Forming Services

5 Axis CNC

Our 5-axis CNC machine can perform complex and precise cutting, milling, and drilling operations on various materials.

5 Axis CNC

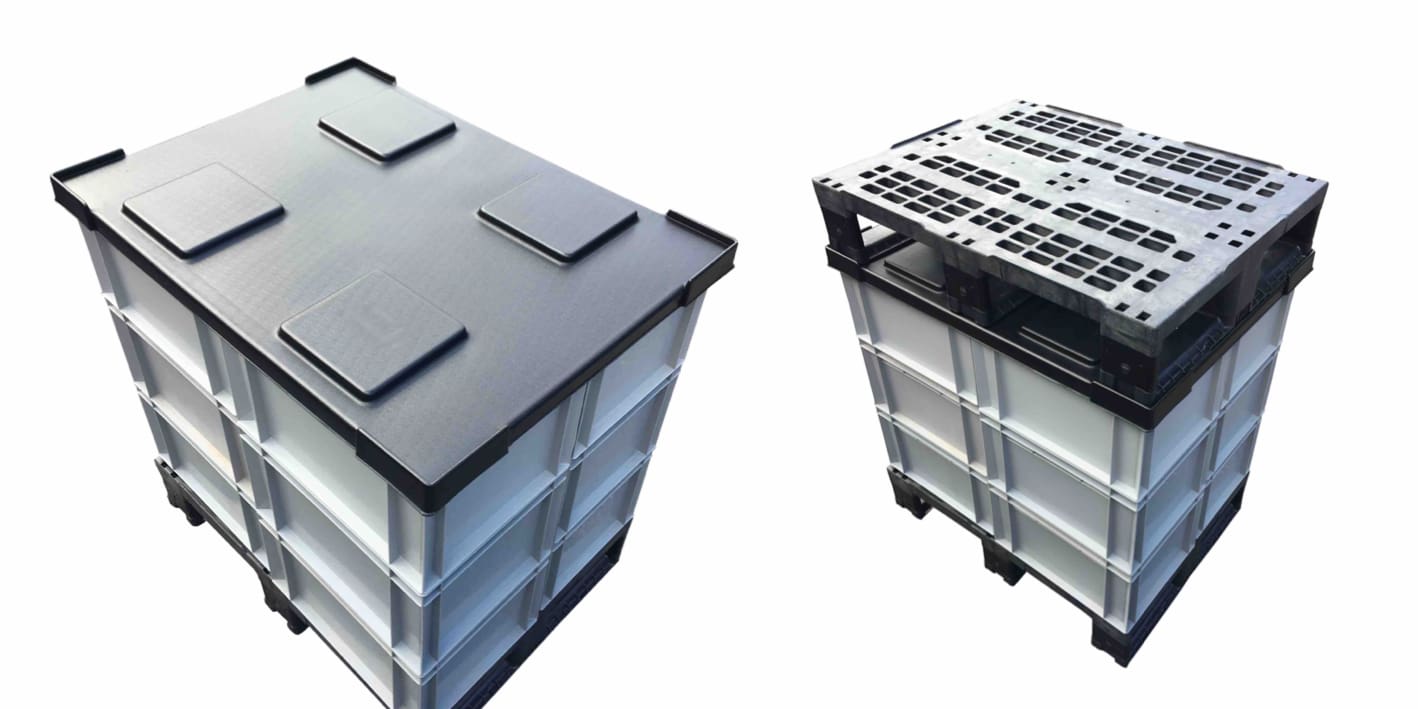

Customised Packaging

We specialise in providing customised packaging solutions tailored to your specific needs.

Customised Packaging

Finished Parts

We are a vacuum forming company that specialises in vacuum moulding custom finished parts.

Plastic Products